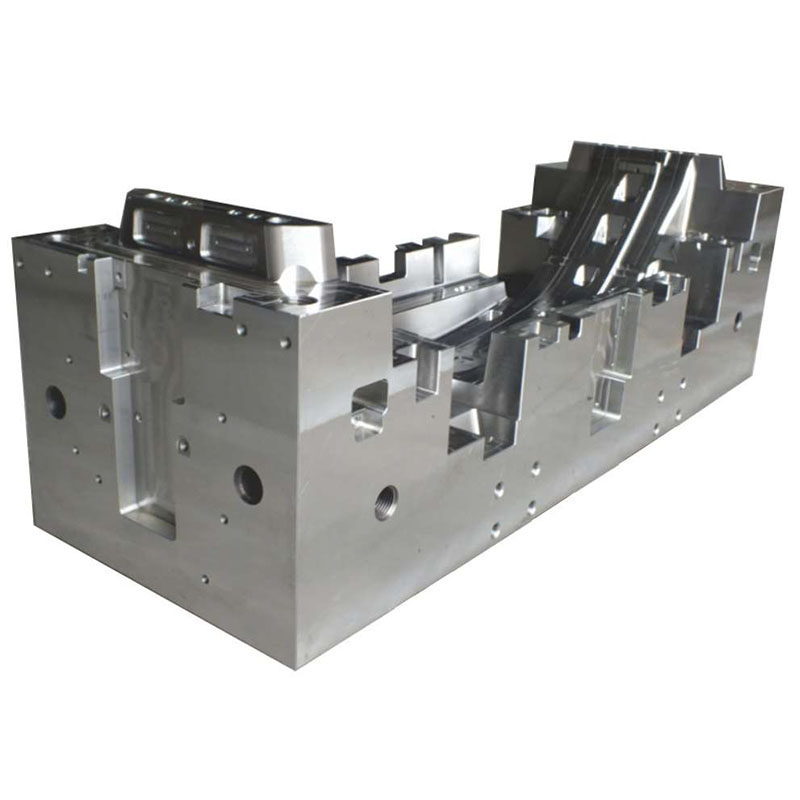

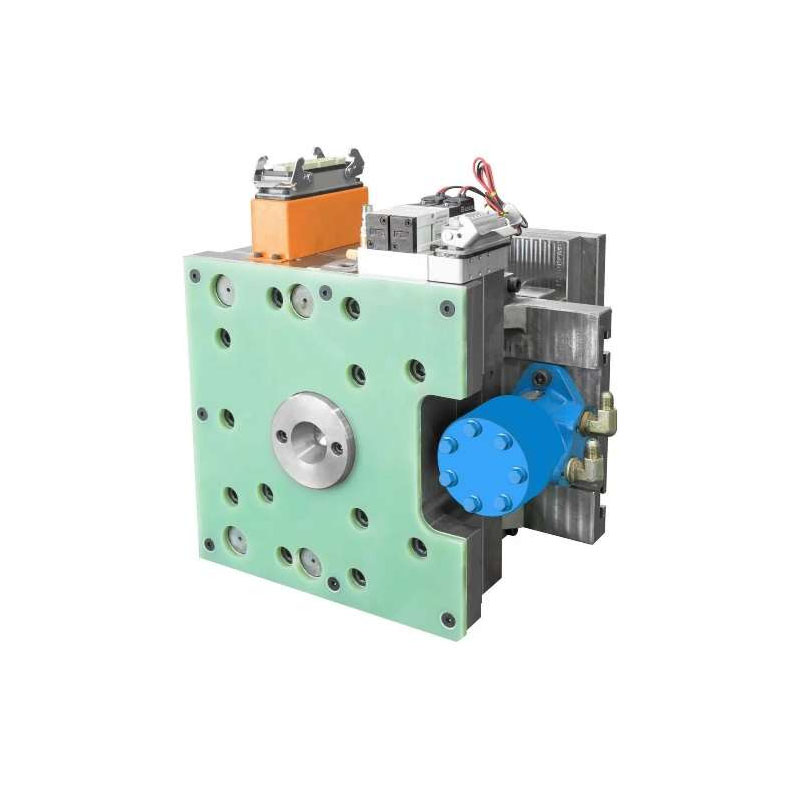

Mold Manufacturing

Injection mold, Die casting mold, Forging die, Stamping mold

Expertise and technology to address your unique design requirements and assembly needs from highly engineered parts to secondary operations to exotic materials.

HOW TO GET AN ACCURATE QUOTE?

The quotation of the mold is affected by many factors, the more accurate the information, the more can help us choose the accurate mold material and provide the best mold design.

• Please provide PDF and 3D drawing or sample of product.

• What is the product material and mold cavity number?

• What is surface requirement of the product?

• What is estimated annual production of product?

• Factory existing injection molding machine information.

• What is the standard of export mold? Is DME,HASCO or DAIDO standard?

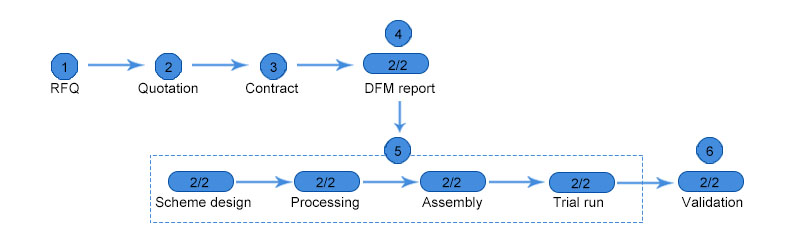

MOLD MANUFACTURING PROCESS

ADVANTAGES OF MOLD MANUFACTURING

We has a number of brand new Japanese Makino, Taiwan Youhong high-precision CNC machining centers, Taiwan Youhong gantry type CNC machining centers, Honghai CNC surface milling machines, CNC gantry precision milling machines and Jiande large stroke high-precision surface grinding machines. These machines help us to easily manufacture injection molds and die casting molds of any size up to 2500 mm. All products shall be inspected with CMM equipment according to the requirements and standards, and the high-precision standards of the industry shall be strictly followed.

• Application selection of various metal materials

Various choices of mold metal materials can be made from a variety of metal and plastic products materials.

• Processing precision range

Multiple tolerance options according to ISO 2768 (standard, fine) and ISO 286v.

• Machining of any size

Mold base & mold processing CNC milling parts with maximum size of 2500 mm for X axis, 1500 mm for Y axis and 600 mm for Z axis.

• Quality assurance

Our quality department implements strict quality control to ensure that the manufacturing process meets customer quality requirements.

• Fast delivery

New CNC milling machines and gantry CNC milling machines can be used to rapidly produce high-precision mold bases and mold processing in 3-14 days.

RELATED LINKS

CNC Precision Machining

Mold Manufacturing

Brass Fitting

Hardware parts customization

Precision Casting

Stamping Parts

Nuts/Screws/Bolts

Valves and fittings in stock

The Other

Get the Custom Part You Need